-

أخر الأخبار

- استكشف

-

الصفحات

-

المجموعات

-

Reels

-

المدونات

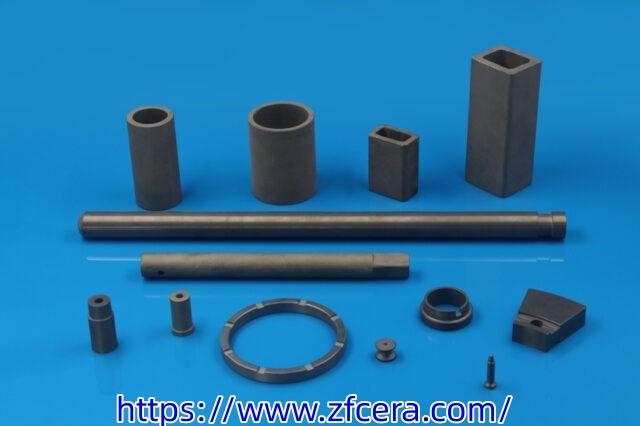

How Can Zhufa Support Your Needs with Custom Silicon Carbide Ceramics?

Zhufa Silicon Carbide Ceramics bring notable characteristics to components designed for environments that involve intense heat, abrasion, or chemical contact. These materials stand out because of their ability to retain strength and shape when exposed to conditions that challenge many alternatives. Industries involved in processing, energy generation, and precision equipment often incorporate such elements where consistent behavior under stress proves valuable. The composition supports hardness that counters wear, along with thermal stability that helps maintain dimensions across wide temperature ranges. This combination allows parts to perform reliably in situations requiring endurance without frequent intervention.

Picture equipment operating in high-temperature zones where ordinary materials soften or deform. Components crafted from this material continue functioning without losing structural integrity. In applications like furnace linings or protective shields, the resistance to thermal shock prevents cracking during rapid heating or cooling cycles. Such resilience keeps operations moving forward smoothly. When abrasive particles move through systems, the surface hardness reduces erosion, preserving shape and function over longer periods. Maintenance teams notice fewer interruptions because wear progresses more slowly compared to less robust options.

Another aspect involves handling corrosive substances. In chemical processing lines or treatment facilities, exposure to acids, alkalis, or aggressive gases can degrade many substances quickly. These components resist such reactions, keeping pathways intact and preventing contamination or leaks. The inert nature supports cleaner processes, especially where purity matters. Flow remains steady, and cleaning becomes less labor-intensive since residues tend not to bond strongly to the surface.

From a mechanical perspective, the material offers a favorable strength-to-weight ratio. Parts can be designed thinner yet still bear significant loads, which aids in creating more compact assemblies. In rotating machinery or sliding mechanisms, low friction characteristics help reduce energy consumption and heat buildup during operation. Bearings, nozzles, or guides benefit from this balance, contributing to quieter performance and extended service intervals. Engineers working on space-constrained projects find the lightweight quality useful for minimizing overall system mass without compromising durability.

Electrical insulation properties open additional possibilities. In devices or assemblies where conductivity needs careful management, these components provide reliable separation. Heat dissipation occurs in a controlled manner, avoiding localized overheating in compact layouts. This trait suits sensors, housings, or supports within electronic or power-related equipment. Stability across temperature swings ensures signals or outputs remain predictable.

Manufacturing approaches allow for detailed shaping and tight tolerances. Techniques enable production of complex geometries that fit specific installation requirements. Surface treatments achieve finishes that further lower friction or improve flow characteristics. Consistency throughout batches supports reliable integration when multiple units are needed. For custom projects or scaled production, flexibility in sizing and configuration accommodates varied demands.

Zhufa represents a name connected with careful fabrication in this domain, emphasizing material integrity and practical design.

Looking at broader uses, these components appear in energy-related equipment where cycling between hot and cold states occurs regularly. Thermal stability prevents stress accumulation, supporting continuous output in fluctuating conditions. In wear-intensive spots such as chutes, valves, or plungers, hardness guards against repeated impact or sliding. The overall effect helps systems run with fewer adjustments.

Customization options allow adaptation to particular needs. Whether refining dimensions, adjusting features, or matching connection types, possibilities exist to align with project goals. Guidance from producers familiar with real-world applications can refine choices and improve outcomes.

For those interested in learning more about these components and their potential fit within operations, https://www.zfcera.com/product/ provides a clear view of available solutions and application details.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness